+86 755 23057280

English

+86 755 23057280

English

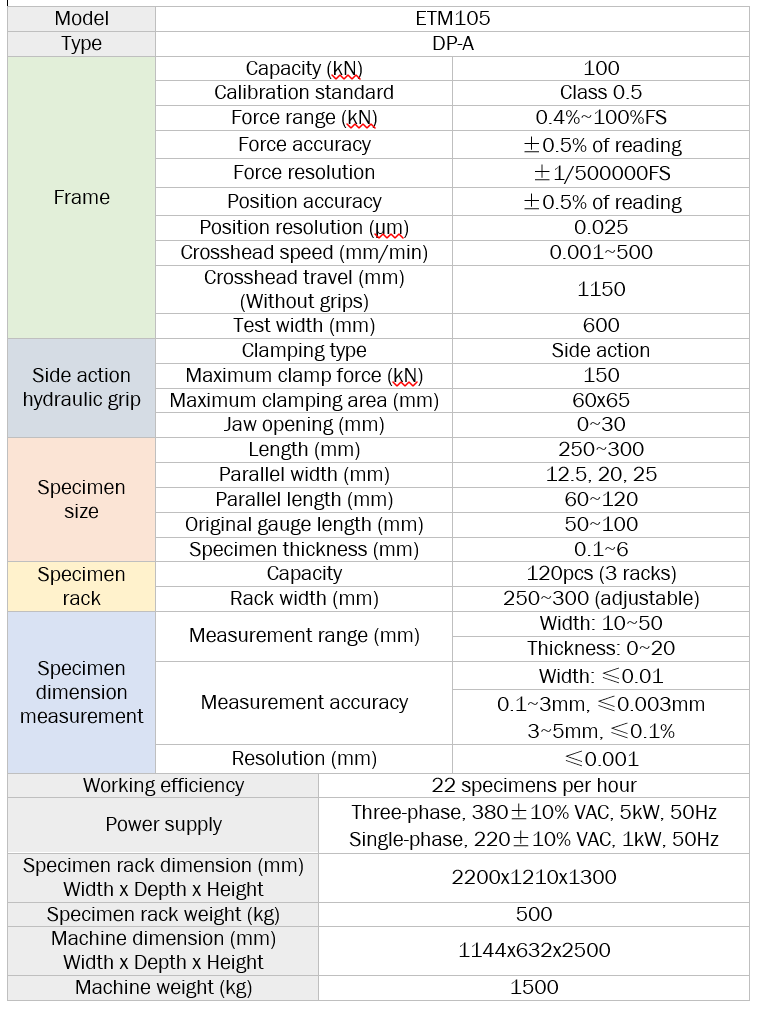

100kN automated tensile testing system consists of electromechanical tensile testing machine, hydraulic side-action grip, hydraulic station, automatic extensometer, cross section measuring device, feeding manipulator, unloading manipulator, sample tray, control system, computer and software, etc. It can realize sampling, automatic cross section measurement, automatic loading, automatic test, automatic unloading, test data processing, test results display, save and upload functions as one of the automatic testing machine equipment.

The system is mainly used for batch tensile test of sheet metal samples with the same or different specifications. It can automatically determine the mechanical tensile properties data such as N and R values, and can automatically calculate and display the real stress and strain values of each characteristic point or user-specified point. Is the iron and steel enterprises, industry quality inspection center, scientific research institutes, colleges and universities, commodity inspection arbitration, technical supervision and other departments for the bulk of sheet metal specimen tensile test of the ideal testing equipment.

Main functions:

The main machine adopts compact structure, high rigidity double column load frame configuration;

Precision pre-loaded ball screw pair; Self-lubricating linear guide device ensures high linear beam movement;

Maintenance-free world class AC servo motors and servers;

Interface sensor with TEDS self-recognition function;

High resolution, digital closed-loop controller; Convenient test setup and handheld;

Adopt hydraulic flat push clamping fixture, clamping reliable and convenient; Ultra silent hydraulic station, noise ≤50dB;

Using cartesian coordinate manipulator sampling, loading, unloading, Germany Siemens PLC as the core control components

Servo motor control action and photoelectric sensors for auxiliary positioning, to ensure the accuracy of manipulator movement;

The cross section measuring device adopts German HEIDENHAIN grating ruler, which is accurate and has automatic calibration function.

Using lever type automatic extender, the sample process automatically tracking measurement, high precision, large measurement range, stable and reliable;

Multi-function, easy to operate pilot software; Equipped with a rich and increasing standard library of test methods (GB, ASTM, ISO, DIN, EN, BS, etc.);

With automatic control and data processing functions; Support data transmission through the network; With real-time test data protection function, in case of accidental power failure, test data can be manually restored.

Dear customers, please send your comments and suggestions to us via the following form. We will contact you as soon as possible.

Scan and follow us

Copyright @Shenzhen Wance Testing Machine Co., Ltd.

All Rights Reserved Design by:zuoan.com.cn